8 Year Exporter Ultrafiltration Mechanism - MBR Membrane Module Reinforced PVDF BM-SLMBR-20 Sewage Treatment – Bangmo

8 Year Exporter Ultrafiltration Mechanism - MBR Membrane Module Reinforced PVDF BM-SLMBR-20 Sewage Treatment – Bangmo Detail:

Product Overview

MBR is a combination of membrane technology and bio-chemical reaction in water treatment. MBR filter the sewage in bio-chemical tank with membrane so that sludge and water are separated. On one hand, membrane rejects microorganisms in the tank, which greatly increase the concentration of activated sludge to a high level, thus the bio-chemical reaction of sewage degradation processes more rapidly and thoroughly. On the other hand, water output is clear and of high quality because of high precision of membrane.

This product adopts reinforced modified PVDF material, which will not peel or break during backwashing, meanwhile it has good permeable rate, mechanical performance, chemical resistance and anti-fouling ability. ID & OD of reinforced hollow fiber membrane are 1.0mm and 2.2mm respectively, filtering precision is 0.1 micron. Filtering direction is outside-in, that is raw water, driven by differential pressure, permeates into the hollow fibers, while bacteria, colloids, suspended solids and microorganisms etc. are rejected in the membrane tank.

Applications

●Treatment, recycle and reuse of industrial waste water;

●Treatment of refuse leachate;

●Upgrade and reuse of municipal sewage.

Filtration Performance

Below filtration effects are proved according to the use of modified PVDF hollow fiber ultrafiltration membrane in different types of water:

| No. | Item | Water Output Index |

| 1 | TSS | ≤1mg/L |

| 2 | Turbidity | ≤1 |

| 3 | CODcr | Removal rate depends on the bio-chemical performance & designed sludge concentration |

| 4 | NH3-H | (Instant removal rate ≤30% without bio-chemical) |

Specifications

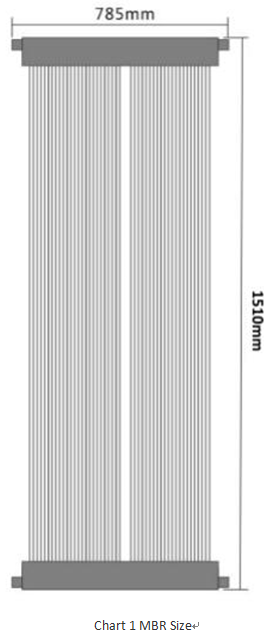

Size

Technical Parameters:

| Filtering Direction | Outside-in |

| Membrane Material | Reinforced Modified PVDF |

| Precision | 0.1 micron |

| Membrane Area | 20m2 |

| Membrane ID/OD | 1.0mm/ 2.2mm |

| Size | 785mm×1510mm×40mm |

| Joint Size | DN32 |

Component Material:

| Component | Material |

| Hollow Fiber Membrane | Reinforced Modified PVDF |

| Sealing Compound | Epoxy Resins + Polyurethane (PU) |

| Housing | ABS |

Using Conditions

Proper pretreatments must be set when raw water contains a lot of impurities/coarse particles or large proportion of grease. Defoamer must be used to remove foams in membrane tank when necessary, please use alcoholic defoamer which is not easy to scale.

| Item | Limit | Remark |

| PH Range | 5-9 (2-12 when washing) | Neutral PH is better for bacterial culture |

| Particle Diameter | <2mm | Prevent sharp particles to scratch membrane |

| Oil & Grease | ≤2mg/L | Prevent membrane fouling/sharp flux decrease |

| Hardness | ≤150mg/L | Prevent membrane scaling |

Application Parameters:

| Designed Flux | 10~25L/m2.h |

| Backwashing Flux | Twice the designed flux |

| Operating Temperature | 5~45°C |

| Maximum Operating Pressure | -50KPa |

| Suggested Operating Pressure | ≤-35KPa |

| Maximum backwashing Pressure | 100KPa |

| Operating Mode | Operate 9min & Stop 1min/Operate 8min & Stop 2min |

| Blowing Mode | Continuous Aeration |

| Aeration Rate | 4m3/h.piece |

| Washing Period | Clean water backwashing every 2~4h; CEB every 2~4 days;Offline washing every 6~12 months(Above information is for reference only, please adjustaccording to actual differential pressure change rule) |

Product detail pictures:

Related Product Guide:

The rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for 8 Year Exporter Ultrafiltration Mechanism - MBR Membrane Module Reinforced PVDF BM-SLMBR-20 Sewage Treatment – Bangmo , The product will supply to all over the world, such as: Monaco, moldova, Uganda, We insist on the principle of Credit being primary, Customers being the king and Quality being the , we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.