factory customized Ultrafiltration Water System - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo

factory customized Ultrafiltration Water System - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo Detail:

Product Overview

MBR is a combination of membrane technology and bio-chemical reaction in water treatment. MBR filter the sewage in bio-chemical tank with membrane so that sludge and water are separated. On one hand, membrane rejects microorganisms in the tank, which greatly increase the concentration of activated sludge to a high level, thus the bio-chemical reaction of sewage degradation processes more rapidly and thoroughly. On the other hand, water output is clear and of high quality because of high precision of membrane.

This product adopts reinforced modified PVDF material, which will not peel or break when backwashing, meanwhile has good permeable rate, mechanical performance, chemical resistance and pollution resistance. ID & OD of reinforced hollow fiber membrane are 1.0mm and 2.2mm respectively, filtration precision is 0.1 micron. Filtration mode is outside-in, that is raw water, driven by differential pressure, permeates into the hollow fibers, while bacteria, colloids, suspended solids and microorganisms etc. are rejected in the membrane tank.

Applications

●Treatment, recycle and reuse of industrial waste water.

●Treatment of refuse leachate.

●Upgrade and reuse of municipal sewage.

Filtration Performance

| No. | Item | Water Output Index |

| 1 | TSS | ≤1mg/L |

| 2 | Turbidity | ≤ 1 |

Specifications

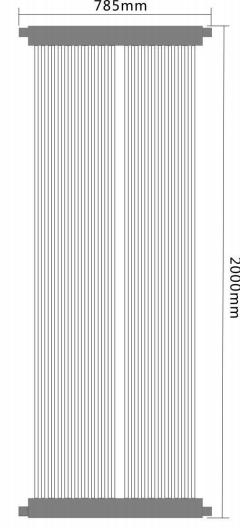

Size

Technical Parameters

| Structure | Outside-in |

| Membrane Material | Reinforced Modified PVDF |

| Precision | 0.1 micron |

| Membrane Area | 25m2 |

| Membrane ID/OD | 1.0mm/ 2.2mm |

| Size | 785mm×2000mm×40mm |

| Joint Size | DN32 |

Component Material

| Component | Material |

| Hollow Fiber Membrane | Reinforced Modified PVDF |

| Sealing Compound | Epoxy Resins + Polyurethane (PU) |

| Housing | ABS |

Application Parameters

| Designed Flux | 10~25L/m2.h |

| Backwashing Flux | 30~60L/m2.h |

| Operating Temperature | 5~45°C |

| Maximum Operating Pressure | -50KPa |

| Suggested Operating Pressure | 0~-35KPa |

| Maximum backwashingPressure | 100KPa |

| Operating Mode | 9min Operation+1min Break/8min Operaetion+2min Break |

| Blowing Mode | Continuous Aeration |

| Aeration Rate | 4m3/h.pc |

| Washing Period | Clean water backwashing every 2~4h; CEB every 2~4 weeks; CIP every 6~12 months |

Using Conditions

There should be appropriate pretreatments before UF. If defoamer has to be used, please choose alcohol defoamer, silicone defoamer is forbidden.

| Item | Value |

| PH Range | 5~9 (washing: 2~12) |

| Particle Size | <2mm, no sharp particles |

| Oil & Grease | ≤2mg/L |

| Hardness | ≤150mg/L |

Product detail pictures:

Related Product Guide:

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for factory customized Ultrafiltration Water System - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo , The product will supply to all over the world, such as: Hyderabad, Georgia, Istanbul, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.