Factory Outlets Purification System - UF Membrane Module 10 inch PVDF Ultrafiltration Membrane Module UFf250 Electroplating Waste Water Treatment – Bangmo

Factory Outlets Purification System - UF Membrane Module 10 inch PVDF Ultrafiltration Membrane Module UFf250 Electroplating Waste Water Treatment – Bangmo Detail:

Applications

Drinking water treatment of tap water, surface water, well water and river water.

Pretreatment of RO.

Treatment, recycle and reuse of industrial waste water.

Filtration Performance

This product is proven to have below filtering effects according to the service conditions of different water sources:

| Ingredient | Effect |

| SS, Particles > 1μm | Removal Rate ≥ 99% |

| SDI | ≤ 3 |

| Bacteria, Viruses | > 4 log |

| Turbidity | < 1NTU |

| TOC | Removal Rate: 0-25% |

*Above data is obtained under the condition that feeding water turbidity is < 25NTU.

Product Parameters

Technical Parameters

| Filtering Type | Outside-in |

| Membrane Material | Modified PVDF |

| MWCO | 200K Dalton |

| Membrane Area | 78m2 |

| Membrane ID/OD | 0.8mm/1.3mm |

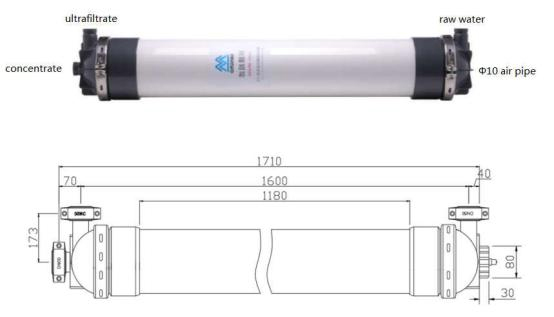

| Dimensions | Φ250mm*1710mm |

| Connector Size | DN50 Clamping |

Application Data

| Pure Water Flux | 15,000L/H (0.15MPa, 25C) |

| Designed Flux | 40-120L/m2.hr (0.15MPa, 25C) |

| Suggested Working Pressure | ≤ 0.2MPa |

| Maximum Transmembrane Pressure | 0.15MPa |

| Maximum Backwashing Pressure | 0.15MPa |

| Air Washing Volume | 0.1-0.15N m3/m2 .hr |

| Air Washing Pressure | ≤ 0.1MPa |

| Maximum Working Temperature | 45C |

| PH Range | Working: 4-10; Washing: 2-12 |

| Operating Mode | Cross Flow |

Feeding Water Requirements

Before feeding water, a security filter < 50 μm should be set to prevent blockage caused by large particles in raw water.

| Turbidity | ≤ 25NTU |

| Oil & Grease | ≤ 2mg/L |

| SS | ≤ 20mg/L |

| Total Iron | ≤ 1mg/L |

| Continuous Residual Chlorine | ≤ 5ppm |

| COD | Suggested ≤ 500mg/L |

*Material of UF membrane is polymer organic plastic, there must not be any organic solvents in raw water.

Operating Parameters

| Backwashing Flow Rate | 100-150L/m2.hr |

| Backwashing Frequency | Every 30-60min. |

| Backwashing Duration | 30-60s |

| CEB Frequency | 0-4 times per day |

| CEB Duration | 5-10min. |

| CIP Frequency | Every 1-3 months |

| Washing Chemicals: | |

| Sterilization | 15ppm Sodium Hypochlorite |

| Organic Pollution Washing | 0.2% Sodium Hypochlorite + 0.1% Sodium Hydroxide |

| Inorganic Pollution Washing | 1-2% Citric Acid/0.2% Hydrochloric Acid |

Component Material

| Component | Material |

| Membrane | Modified PVDF |

| Sealing | Epoxy Resins |

| Housing | UPVC |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Factory Outlets Purification System - UF Membrane Module 10 inch PVDF Ultrafiltration Membrane Module UFf250 Electroplating Waste Water Treatment – Bangmo , The product will supply to all over the world, such as: Karachi, Colombia, Greenland, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate.

We have worked with many companies, but this time is the ,detailed explanation, timely delivery and quality qualified, nice!

Write your message here and send it to us