New Delivery for Mbr Plant - MCR Membrane Module Reinforced PVDF BM-SLMCR-20 RO Pretreatment – Bangmo

New Delivery for Mbr Plant - MCR Membrane Module Reinforced PVDF BM-SLMCR-20 RO Pretreatment – Bangmo Detail:

Product Overview

Submerged ultrafiltration (MCR) Technology is a water treatment technology which combines membrane technology and physico-chemical precipitation process. High-precision sludge-water separation of outlet from coagulation sedimentation tank can be done by submerged ultrafiltration (MCR), high filtering precision of memrbane insures high quality and clear water outlet.

This product adopts reinforced modified PVDF material, which will not peel or break during backwashing, meanwhile it has good permeable rate, mechanical performance, chemical resistance and anti-fouling ability. ID & OD of reinforced hollow fiber membrane are 1.0mm and 2.2mm respectively, filtering precision is 0.03 micron. Filtering direction is outside-in, that is raw water, driven by differential pressure, permeates into the hollow fibers, while bacteria, colloids, suspended solids and microorganisms etc. are rejected in the membrane tank.

Applications

● Purification of surface water;

● Reuse of heavy metal waste water;

● Pretreatment of RO.

Filtration Performance

Below filtration effects are proved according to the use of modified PVDF hollow fiber ultrafiltration membrane in different types of water:

| No. | Item | Water Output Index |

| 1 | TSS | ≤1mg/L |

| 2 | Turbidity | ≤ 1 |

Specifications

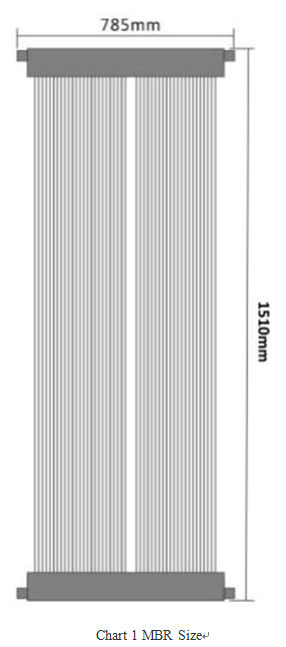

Size

Chart 1 MBR Size

Technical Parameters:

| Filtering Direction | Outside-in |

| Membrane Material | Reinforced Modified PVDF |

| Precision | 0.03 micron |

| Membrane Area | 20m2 |

| Membrane ID/OD | 1.0mm/ 2.2mm |

| Size | 785mm×1510mm×40mm |

| Joint Size | DN32 |

Component Material:

| Component | Material |

| Hollow Fiber Membrane | Reinforced Modified PVDF |

| Sealing Compound | Epoxy Resins + Polyurethane (PU) |

| Housing | ABS |

Using Conditions

Proper pretreatments must be set when raw water contains a lot of impurities/coarse particles or large proportion of grease. Defoamer must be used to remove foams in membrane tank when necessary, please use alcoholic defoamer which is not easy to scale.

| Item | Limit | Remark |

| PH Range | 5-9 (2- 12 when washing) | Neutral PH is better for bacterial culture |

| Particle Diameter | <2mm | Prevent sharp particles to scratch membrane |

| Oil & Grease | ≤2mg/L | Prevent membrane fouling/sharp flux decrease |

| Hardness | ≤150mg/L | Prevent membrane scaling |

Application Parameters:

| Designed Flux | 15~40L/m2.h |

| Backwashing Flux | Twice the designed flux |

| Operating Temperature | 5~45°C |

| Maximum Operating Pressure | -50KPa |

| Suggested Operating Pressure | ≤-35KPa |

| Maximum backwashing Pressure | 100KPa |

| Operating Mode | Continuous opeartion, intermittent backwashing air flushing |

| Blowing Mode | Continuous Aeration |

| Aeration Rate | 4m3/h.piece |

| Washing Period | Clean water backwashing every 1~2h; CEB every 1~2 days;Offline washing every 6~12 months(Above information is for reference only, please adjustaccording to actual differential pressure change rule) |

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we've acquired rich practical working experience in producing and managing for New Delivery for Mbr Plant - MCR Membrane Module Reinforced PVDF BM-SLMCR-20 RO Pretreatment – Bangmo , The product will supply to all over the world, such as: Albania, Sydney, Albania, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!