Bangmo has core technology and large-scale production capacity of high-end separating membrane. Its main products, pressurized hollow fiber ultrafiltration membrane module, submerged MBR membrane module and submerged ultrafiltration (MCR) module, are widely used in the fields of water purification, sewage treatment, wastewater reuse, etc., and have been exported to the regions of Europe, U.S., Middle East, Africa, Southeast Asia, etc.

Bangmo focuses on R&D of new technology and transformation of scientific research achievement. It has a membrane R&D team, composed of membrane separating technology specialists and professional technicians, and keeps close technical communication and application cooperation with Tianjin Polytechnic University, South China University of Technology and Duke University Marine Laboratory.

Factory Introduction

Bangmo factory locates in Lian’gang Industrial Area, Jinwan District, Zhuhai, plant area is over 8000 square meters, number of skilled workers is over 50.

Hollow fiber production workshop

Bangmo has 10 production lines of hollow fiber membrane, annual output is over 3,500,000 square meters.

Assembling, testing workshop and laboratory

Fully equipped with hollow fiber membrane detecting instrument and water quality testing instrument.

Why Choose Us

Corporate Culture

Specialization

Since 1993, Bangmo has always been specializing in the R&D and production of hollow fiber ultrafiltration (UF) membrane and membrane bioreactor (MBR). Our professional team has separated technology specialists, engineers, and experienced technicians in water treatment.

We have a nearly 30-year track record of manufacturing, developing, constructing and operating equipment for water-treatment and specialty separation in leading technology.

Innovation

Bangmo has high requirements and high standards when selecting raw materials, and will never compromise to cut the costs. Bangmo products are 100% inspected before leaving factory so that they will be in best condition when reaching customers.

Bangmo combines innovative cutting-edge technology with our decades of experience to create our product in premium quality.

Quality

We place innovation at the center, focused on developing industry leading technology to produce higher performance, longer durability, and better-quality membrane system. As a High and New Tech Enterprises, we incessantly invest on research and develop advance technology with our intellectual property.

We have established strategic partnerships with leading research institutes and universities to strengthen our innovation capability.

Sustainability

We understand the responsibility towards our planet, our communities, and our customers, so we reduce our environmental footprint by design our products and manufacturing processes to be less carbon-intensive through thoughtful material selection, increased efficiency, and greater product longevity.

We hold ourselves and our suppliers to the highest standards of labor, health and safety, and environmental stewardship.

R & D

20+ research professionals with years of experience in membrane technology

Multiple authorized patents, state-of-the-art pilot production line

Close cooperation with research institution and top universities

Established of R&D innovation platforms

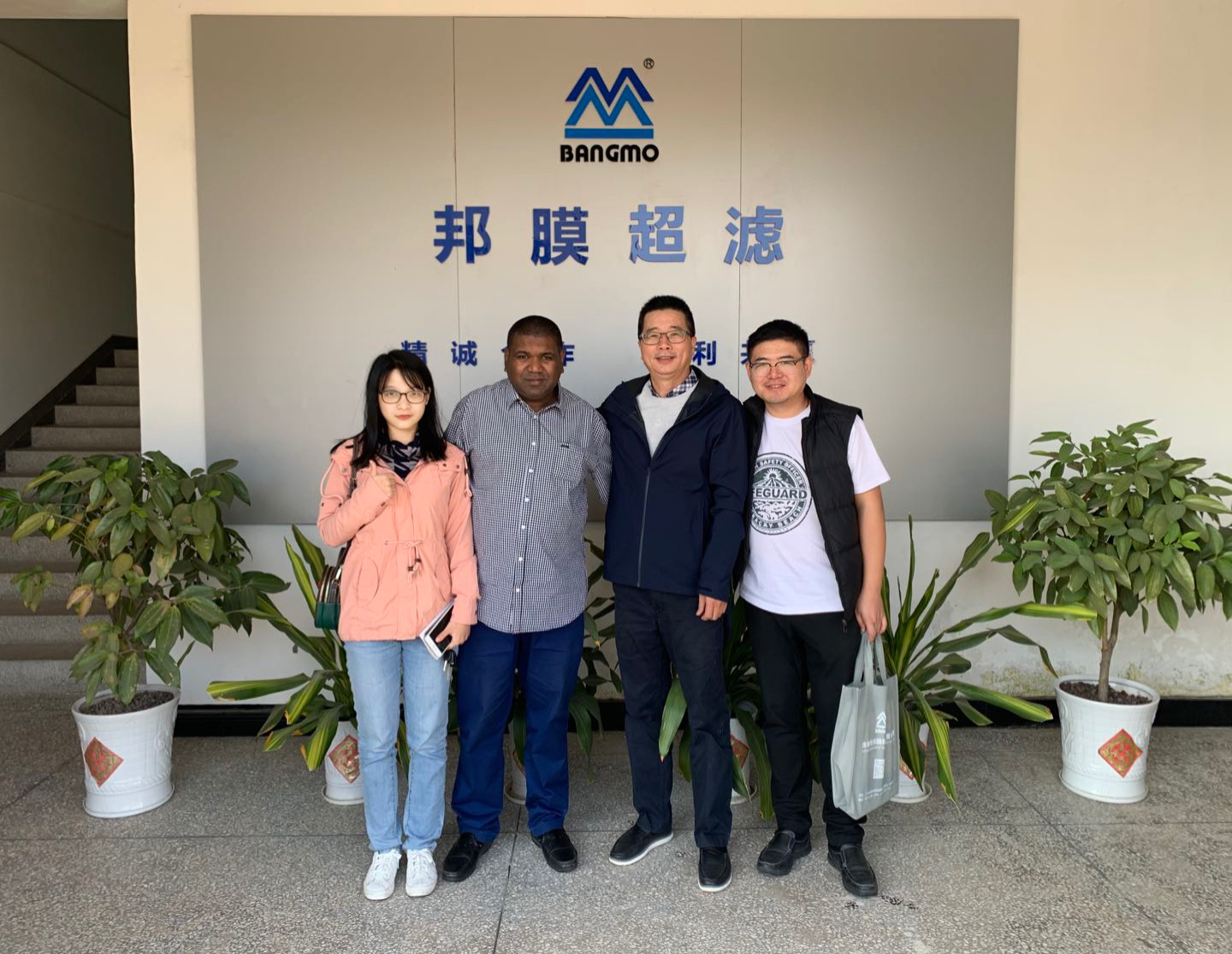

Industry Partner

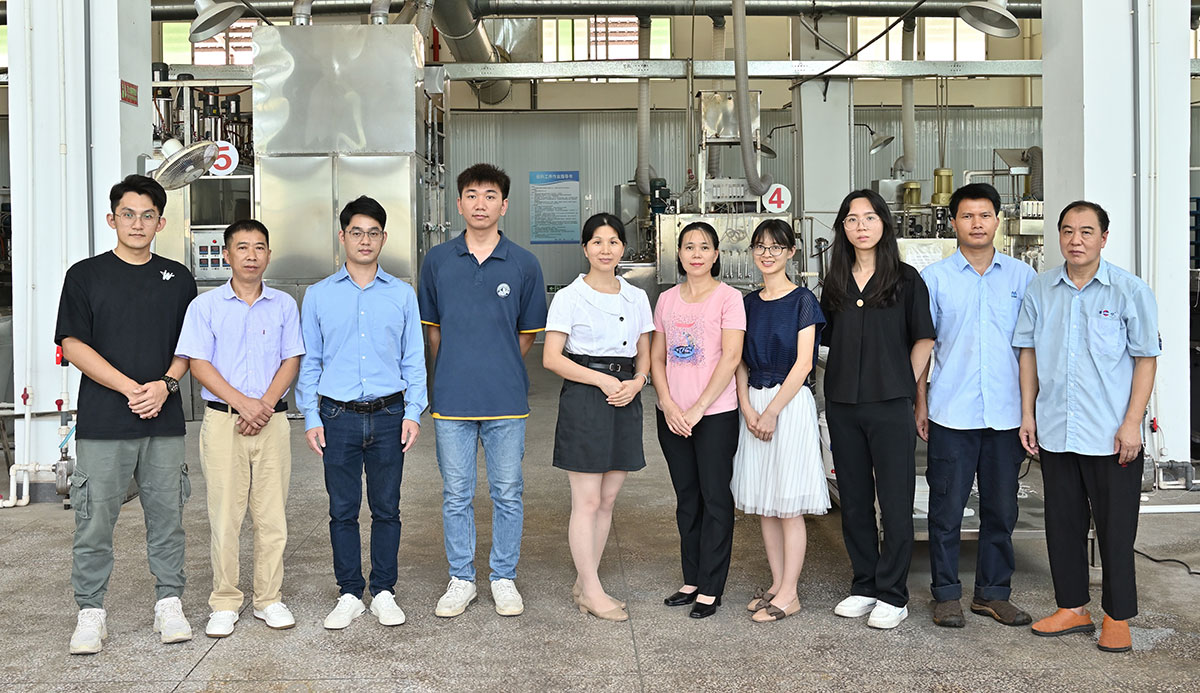

Our Team

Managing Director

Sales Department

Technical Department

QC Department

Production Department