UF Membrane Module PVC Ultrafiltration Membrane Module UFc80C Stainless Steel Housing Rain Water Treatment

Applications

●Production of mineral water, mountain spring water and other germ-free liquid.

●Drinking treatment of tap water, surface water, well water and river water.

●Pre-treatment of RO device.

●Treatment, recycle and reuse of industrial wastewater.

Filtration Performance

According to the service conditions of modified PVC hollow fiber ultrafiltration membrane which are applied to various water sources, the product is proved to reach below filtration effects:

| Water Composition | Filtering Effect |

| Suspended Substances, Particles >1um | Removal Rate ≥99% |

| SDI | ≤ 3 |

| Virus, Bacteria | >4 log |

| Turbidity | <0.1NTU |

| TOC | Removal Rate 0-25% |

Above data is obtained when turbidity of feed water is less than 15NTU. The product is proved to reach the sanitary standards of drinking water by Health Department of Guangdong Province. Approval number is YUE WEI SHUI ZI 2014 S1671.

Product Parameters

Product Appearance

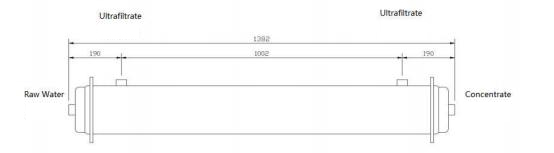

Figure 1 Product Dimensions

Technical Parameters

| Structure | inside-out |

| Membrane Material | Modified PVC |

| MWCO | 100K Dalton |

| Nominal Membrane Area | 16.5m2 |

| Membrane ID/OD | 1.0mm/1.8mm |

| Module Dimensions | Φ180mm×1382mm |

| Connector Dimensions | DN25 Female Thread |

Application Data

| Pure Water Flux | 7,000L/H (0.15MPa, 25℃) |

| Designed Flux | 35-100L/H (0.15MPa, 25℃) |

| Operating Pressure | ≤0.2MPa |

| Maximum Trans Membrane Pressure | 0.2MPa |

| Maximum Operating Temperature | 45℃ |

| Operating PH Range | 4-10 |

| Washing PH Range | 2-12 |

| Operating Mode | Cross-flow/Dead-end Filtration |

Feed Water Requirements

A security filter, precision <50 micron, should be set as pretreatment of UF, in case of blockage caused by large particles in raw water. Attention: UF membrane material is macromolecular organic plastics, raw water must not contain any organic solvents.

| Feed Water Turbidity | ≤15NTU |

| Oil & Grease | ≤2mg/L |

| Feed Water SS | ≤20mg/L |

| Total Iron | ≤1mg/L |

| Continuous Feeding Residual Chlorine | ≤5ppm |

| COD | Suggested ≤500mg/L |

Component Material

| Component | Material |

| Membrane | Modified PVC |

| Sealing | Epoxy Resins |

| Housing | SUS304 |

Typical Operating Parameters

| Maximum Backwashing Pressure | 0.2MPa | |

| Backwashing Flow Rate | 100-150L/m2 .h | |

| Backwashing Frequency | Every 30-60 minutes | |

| Backwashing Duration | 30-60 seconds | |

| CEB Frequency | 0-4 times/day | |

| CEB Duration | 5-10 minutes | |

| CIP Frequency | 1-3 months | |

| General Washing Chemicals : | ||

| Disinfection | 15ppm NaClO | |

| Organic Contamination Washing | 0.2% NaClo+0.1% NaOH | |

| Inorganic Contamination Washing | 1-2% Citric Acid /0.2% HCl | |